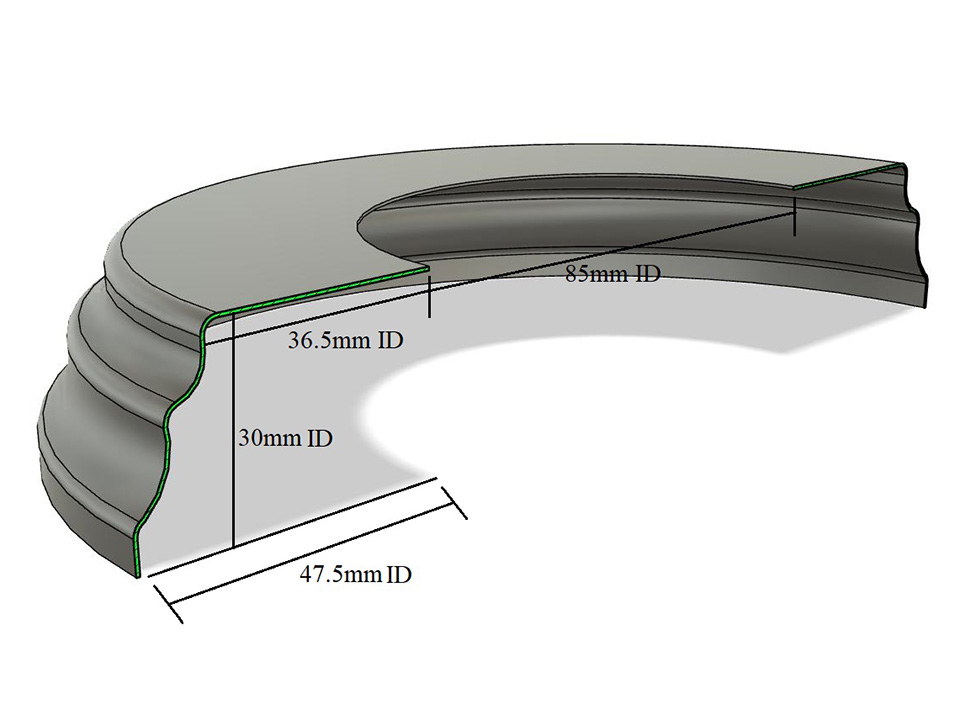

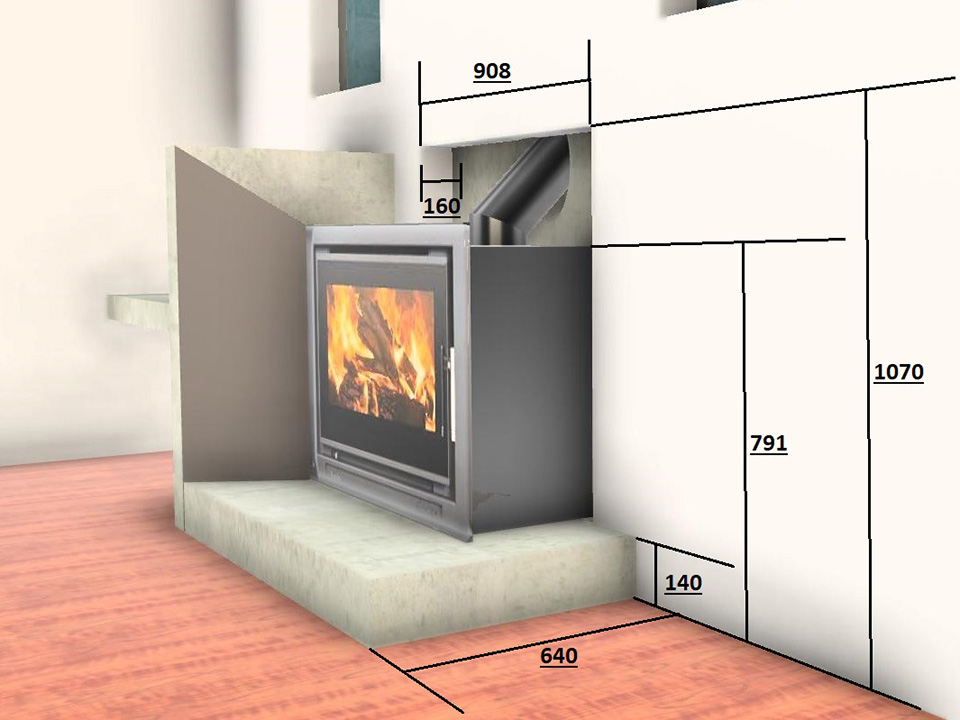

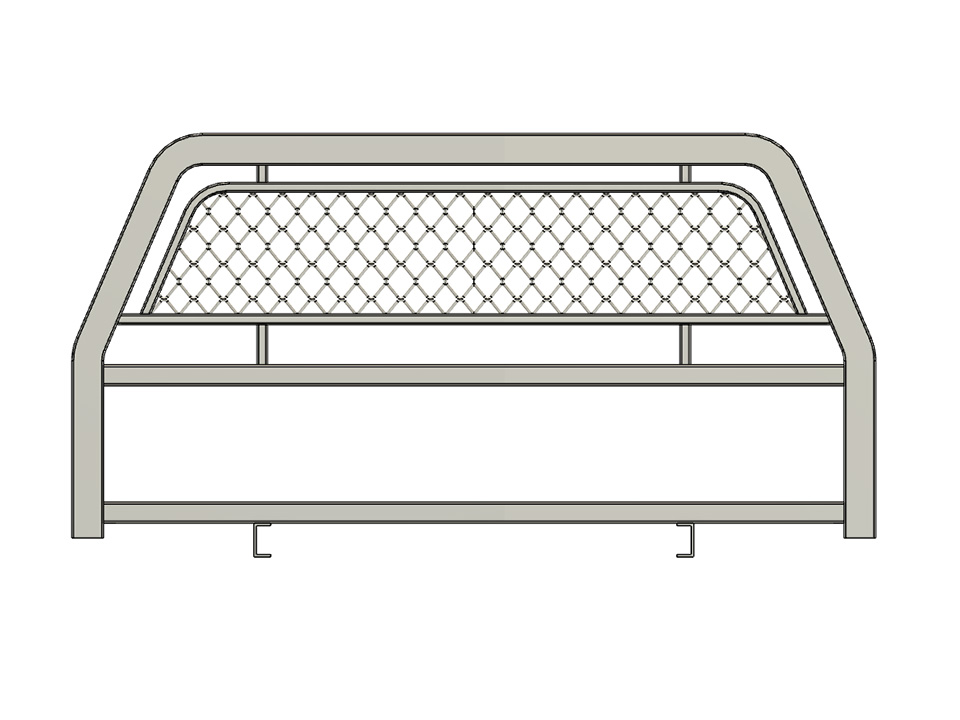

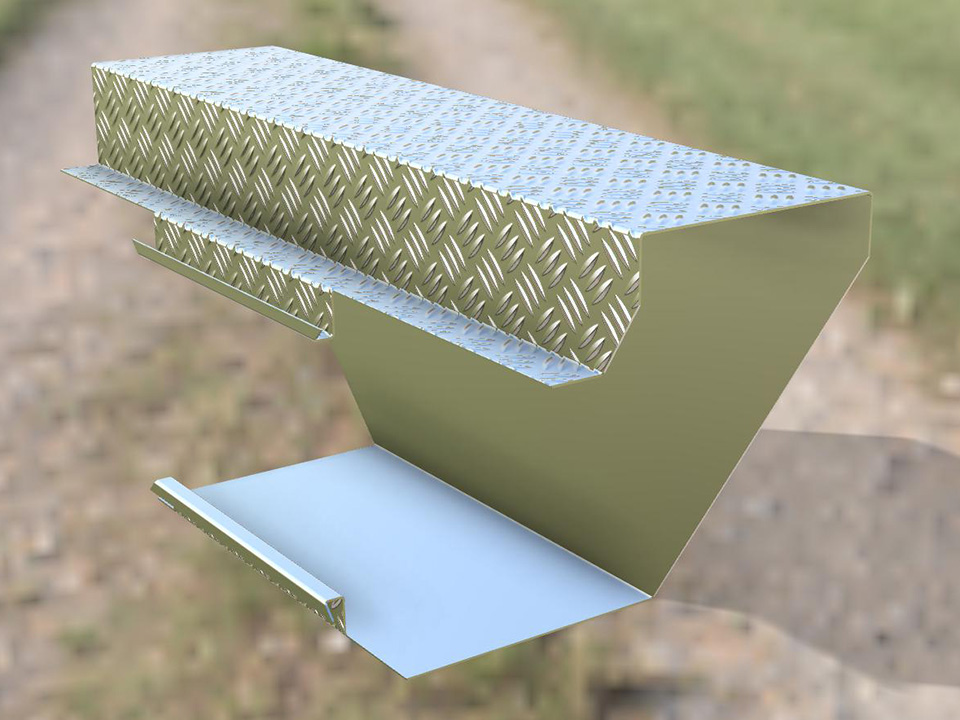

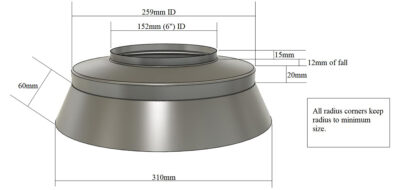

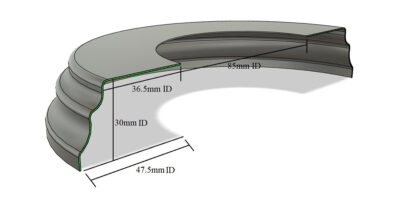

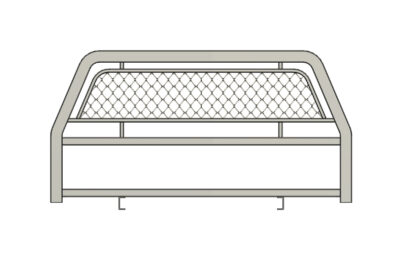

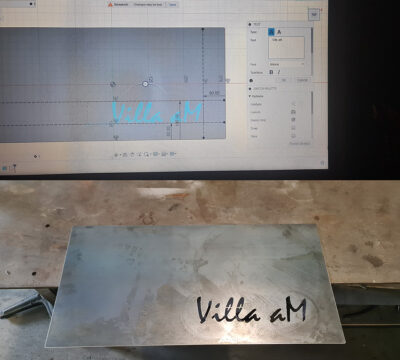

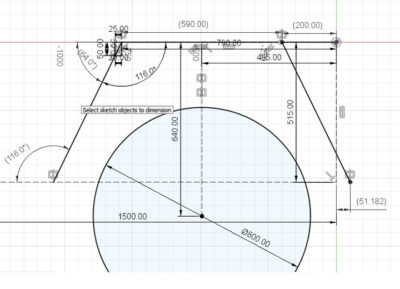

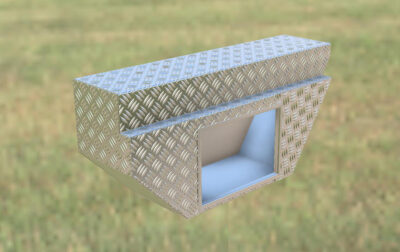

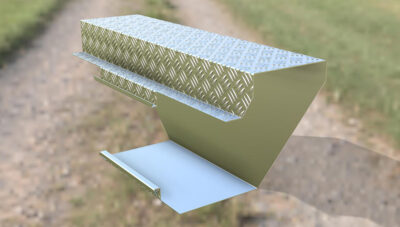

At Attards Metal and Heaters we enjoy a challenging job, and in some cases a project is better designed in a CAD program. We use CAD design to provide the customer or ourselves with a look at what the finished product could look like. Sometimes we are building a complex part with lots of slots or holes, and it is more practical and cost effective to get the job laser cut.

Don’t get us wrong we love doing pattern layouts (old-school way) to produce jobs but in this day and age we realise and make use of the technology available.

We have a lot of experience designing parts for flue kits, heater fascia’s, signs, toolboxes, canopies, mud guards, heritage trims, stainless cooking surrounds, and we often use a CAD drawing layout to check if a customer’s heater will fit in a certain position or on an existing hearth.